Ceramics

Normal Porcelain C - 112

Basically Alkaline AluminoSilicate are economic insulator, good mechanical strength, good resistance to chemical attack and widely popular.

Properties \ Material |

Unit |

|

Equivalent to DIN EN 60672 |

|

C-112 |

Main Ingredients\Composition |

SiO 2% |

70 |

Physical Properties |

||

Color |

|

Cream/White/Grey |

Specific Gravity |

|

2.3 |

Water Absorption |

% |

0 |

Flexural Strength |

KG/CM2 |

800 |

Compressive Strength |

KG/CM2 |

1500 |

Young's Modulus |

KG/CM2 x 106 |

0.7 |

Hardness |

Moh's |

6-6.5 |

Thermal Properties |

||

Co-efficient of Thermal Expansion |

10-6/°K |

5-6 |

Thermal Shock Resistance Down Shock T |

°C |

200 |

Thermal Conductivity |

W / M°K |

1.4 - 2.5 |

Max. Temp. Withstanding Capacity |

°C |

600 |

Electrical Properties |

||

Dielectric Strength (20C) |

KV / mm |

8 |

Dielectric Content (20C : : 1MHz) |

|

5 |

Volume Resistivity (20C) |

Ohm-cm |

1011 |

Application |

||

LT Insulator/Grinding media Lining Block |

||

Alumina Porcelain C - 120

Alkaline AluminaSilicate,with High Alumino contents high mechanical strength, high voltage resistivity and excellent electric insulation.

Properties \ Material |

Unit |

|

Equivalent to DIN EN 60672 |

|

C-120 |

Main Ingredients\Composition |

SiO 2% |

55 |

Physical Properties |

||

Color |

|

White with coffee brown glaze |

Specific Gravity |

|

2.4 |

Water Absorption |

% |

0 |

Flexural Strength |

KG/CM2 |

900 |

Compressive Strength |

KG/CM2 |

2000 |

Young's Modulus |

KG/CM2 x 106 |

0.8 |

Hardness |

Moh's |

6 - 6.5 |

Thermal Properties |

||

Co-efficient of Thermal Expansion |

10-6/°K |

6 - 8 |

Thermal Shock Resistance Down Shock T |

°C |

250 |

Thermal Conductivity |

W / M°K |

1.4 - 2.6 |

Max. Temp. Withstanding Capacity |

°C |

700 |

Electrical Properties |

||

Dielectric Strength (20C) |

KV / mm |

12 |

Dielectric Content (20C : : 1MHz) |

|

6 |

Volume Resistivity (20C) |

Ohm-cm |

1011 |

Application |

||

H.T. Fuse Body with Core & H.T. Insulators |

||

Steatite Grade L – 3 C – 220

Primarily Magnesia Silicate, impervious material structure, economical low, mechanical strength and good volume resistivity.

Properties \ Material |

Unit |

|

Equivalent to DIN EN 60672 |

|

C-220 |

Main Ingredients\Composition |

SiO 2% |

50 |

Physical Properties |

||

Color |

|

Off White |

Specific Gravity |

|

2.5 |

Water Absorption |

% |

0 |

Flexural Strength |

KG/CM2 |

1200 |

Compressive Strength |

KG/CM2 |

2500 |

Young's Modulus |

KG/CM2 x 106 |

0.8 |

Hardness |

Moh's |

6 - 7 |

Thermal Properties |

||

Co-efficient of Thermal Expansion |

10-6/°K |

4 - 7 |

Thermal Shock Resistance Down Shock T |

°C |

190 |

Thermal Conductivity |

W / M°K |

2 - 3 |

Max. Temp. Withstanding Capacity |

°C |

500 |

Electrical Properties |

||

Dielectric Strength (20C) |

KV / mm |

10 |

Dielectric Content (20C : : 1MHz) |

|

5.5 |

Volume Resistivity (20C) |

Ohm-cm |

1011 |

Application |

||

MCB Plates Beads. |

||

Steatite Grade L – 5 C – 221

Basically Magnesia silicate, impervious material structure, very good mechanical strength, high volume resistivity up to 1000 degree C, low dissipation factor, good dielectric strength and very popular.

Properties \ Material |

Unit |

|

Equivalent to DIN EN 60672 |

|

C-221 |

Main Ingredients\Composition |

SiO 2% |

60 |

Physical Properties |

||

Color |

|

Off White |

Specific Gravity |

|

2.7 |

Water Absorption |

% |

0 |

Flexural Strength |

KG/CM2 |

1400 |

Compressive Strength |

KG/CM2 |

3000 |

Young's Modulus |

KG/CM2 x 106 |

1.1 |

Hardness |

Moh's |

6 - 7 |

Thermal Properties |

||

Co-efficient of Thermal Expansion |

10-6/°K |

7 - 9 |

Thermal Shock Resistance Down Shock T |

°C |

190 |

Thermal Conductivity |

W / M°K |

2 - 3 |

Max. Temp. Withstanding Capacity |

°C |

500 |

Electrical Properties |

||

Dielectric Strength (20C) |

KV / mm |

15 |

Dielectric Content (20C : : 1MHz) |

|

6.5 |

Volume Resistivity (20C) |

Ohm-cm |

1011 |

Application |

||

HRC Square Bodies/ Thermostat Parts/ Band Heaters/End Seal Bush/ Grinding Media. |

||

Cordierite Porcelain C - 410

Basically Alumino Silicate contains Cordierite Impervious material structure, high resistance to thermal shock, very low linear expansion and good mechanical strength.

Properties \ Material |

Unit |

|

Equivalent to DIN EN 60672 |

|

C-410 |

Main Ingredients\Composition |

SiO 2% |

60 |

Physical Properties |

||

Color |

|

White |

Specific Gravity |

|

2.3 |

Water Absorption |

% |

0 |

Flexural Strength |

KG/CM2 |

600 |

Compressive Strength |

KG/CM2 |

2000 |

Young's Modulus |

KG/CM2 x 106 |

0.75 |

Hardness |

Moh's |

6 - 6.5 |

Thermal Properties |

||

Co-efficient of Thermal Expansion |

10-6/°K |

2 - 4 |

Thermal Shock Resistance Down Shock T |

°C |

250 |

Thermal Conductivity |

W / M°K |

1.2 - 2.5 |

Max. Temp. Withstanding Capacity |

°C |

600 |

Electrical Properties |

||

Dielectric Strength (20C) |

KV / mm |

10 |

Dielectric Content (20C : : 1MHz) |

|

6 |

Volume Resistivity (20C) |

Ohm-cm |

1010 |

Application |

||

HRC Round Bodies/ Wire Wound Resistors/Tubes. |

||

Cordierite Refractory C - 511

Contains magnesia alumino silicate, porous material structure, low mechanical strength,high resistance to thermal shock and low linear expansion.

Properties \ Material |

Unit |

|

Equivalent to DIN EN 60672 |

|

C-511 |

Main Ingredients\Composition |

SiO 2% |

50 |

Physical Properties |

||

Color |

|

Brown |

Specific Gravity |

|

1.9 |

Water Absorption |

% |

20 |

Flexural Strength |

KG/CM2 |

250 |

Compressive Strength |

KG/CM2 |

1200 |

Young's Modulus |

KG/CM2 x 106 |

- |

Hardness |

Moh's |

- |

Thermal Properties |

||

Co-efficient of Thermal Expansion |

10-6/°K |

4 - 6 |

Thermal Shock Resistance Down Shock T |

°C |

350 |

Thermal Conductivity |

W / M°K |

1.3 - 1.8 |

Max. Temp. Withstanding Capacity |

°C |

1100 |

Electrical Properties |

||

Dielectric Strength (20C) |

KV / mm |

- |

Dielectric Content (20C : : 1MHz) |

|

- |

Volume Resistivity (20C) |

Ohm-cm |

- |

Application |

||

Bobbins/Multi Hole Tubes. |

||

High Alumina Refractory C - 510

>60% Alumina, porous material, structure low, mechanical strength, high refractoriness.

Properties \ Material |

Unit |

|

Equivalent to DIN EN 60672 |

|

C-510 |

Main Ingredients\Composition |

SiO 2% |

30 |

Physical Properties |

||

Color |

|

Milky White |

Specific Gravity |

|

2.0 |

Water Absorption |

% |

30 |

Flexural Strength |

KG/CM2 |

250 |

Compressive Strength |

KG/CM2 |

800 |

Young's Modulus |

KG/CM2 x 106 |

- |

Hardness |

Moh's |

- |

Thermal Properties |

||

Co-efficient of Thermal Expansion |

10-6/°K |

3 - 6 |

Thermal Shock Resistance Down Shock T |

°C |

250 |

Thermal Conductivity |

W / M°K |

1.2 - 1.7 |

Max. Temp. Withstanding Capacity |

°C |

1200 |

Electrical Properties |

||

Dielectric Strength (20C) |

KV / mm |

- |

Dielectric Content (20C : : 1MHz) |

|

- |

Volume Resistivity (20C) |

Ohm-cm |

- |

Application |

||

Sp. Shape Refractories for elec. furnaces. |

||

Hard Porcelain C - 610

Alumino Silicate contains more than 50% Alumina, Impervious material structure, excellent mechanical strength, high thermal conductivity.

Properties \ Material |

Unit |

|

|

Equivalent to DIN EN 60672 |

|

C-610 |

|

Main Ingredients\Composition |

SiO 2% |

40 |

|

Physical Properties |

|||

Color |

|

White |

|

Specific Gravity |

|

2.6 |

|

Water Absorption |

% |

0 |

|

Flexural Strength |

KG/CM2 |

1200 |

|

Compressive Strength |

KG/CM2 |

3500 |

|

Young's Modulus |

KG/CM2 x 106 |

1.0 |

|

Hardness |

Moh's |

7 |

|

Thermal Properties |

|||

Co-efficient of Thermal Expansion |

10-6/°K |

5 - 7 |

|

Thermal Shock Resistance Down Shock T |

°C |

300 |

|

Thermal Conductivity |

W / M°K |

2.6 |

|

Max. Temp. Withstanding Capacity |

°C |

800 |

|

Electrical Properties |

|||

Dielectric Strength (20C) |

KV / mm |

10 |

|

Dielectric Content (20C : : 1MHz) |

|

7 |

|

Volume Resistivity (20C) |

Ohm-cm |

1011 |

|

Application |

|||

High/Low Voltage electrical application/Formers. |

|||

Alumina Ceramic C - 780

Impervious material structure, high mechanical strength, high wear resistance, high thermal conductivity, high heat resistance and high chemical resistance.

Properties \ Material |

Unit |

|

Equivalent to DIN EN 60672 |

|

C-780 |

Main Ingredients\Composition |

SiO 2% |

- |

Physical Properties |

||

Color |

|

Dark Brown |

Specific Gravity |

|

3.2 |

Water Absorption |

% |

0 |

Flexural Strength |

KG/CM2 |

2000 |

Compressive Strength |

KG/CM2 |

6000 |

Young's Modulus |

KG/CM2 x 106 |

2.0 |

Hardness |

Moh's |

8 |

Thermal Properties |

||

Co-efficient of Thermal Expansion |

10-6/°K |

6.8 |

Thermal Shock Resistance Down Shock T |

°C |

250 |

Thermal Conductivity |

W / M°K |

10 - 16 |

Max. Temp. Withstanding Capacity |

°C |

1000 |

Electrical Properties |

||

Dielectric Strength (20C) |

KV / mm |

12 |

Dielectric Content (20C : : 1MHz) |

|

8 |

Volume Resistivity (20C) |

Ohm-cm |

1012 |

Application |

||

Coil Formers/Wear Res. Parts. |

||

High Alumina Ceramic C - 786

Impervious material structure, high mechanical strength, high wear resistance, high thermal conductivity, high heat resistance and high chemical resistance.

Properties \ Material |

Unit |

|

Equivalent to DIN EN 60672 |

|

C-786 |

Main Ingredients\Composition |

SiO 2% |

- |

Physical Properties |

||

Color |

|

Pink / White |

Specific Gravity |

|

3.5 |

Water Absorption |

% |

0 |

Flexural Strength |

KG/CM2 |

2500 |

Compressive Strength |

KG/CM2 |

12000 |

Young's Modulus |

KG/CM2 x 106 |

2.2 |

Hardness |

Moh's |

9 |

Thermal Properties |

||

Co-efficient of Thermal Expansion |

10-6/°K |

6.8 |

Thermal Shock Resistance Down Shock T |

°C |

350 |

Thermal Conductivity |

W / M°K |

14 - 24 |

Max. Temp. Withstanding Capacity |

°C |

1300 |

Electrical Properties |

||

Dielectric Strength (20C) |

KV / mm |

15 |

Dielectric Content (20C : : 1MHz) |

|

9 |

Volume Resistivity (20C) |

Ohm-cm |

1012 |

Application |

||

Pump Seal Faces / Flexible Band Heaters / Thread Guides. |

||

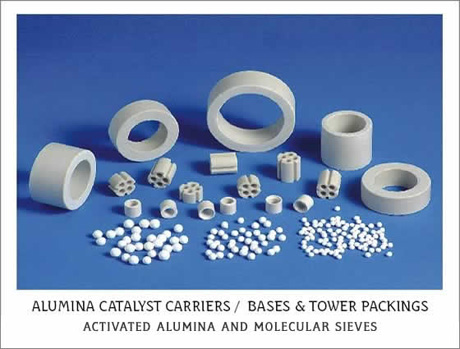

Activated Alumina Ceramic C( As per Customer Application Specification )

Catalyst Carriers/Base, Molecular Sieves, Ceramic Balls for Activated Alumina Bed.