Energy Regulators

Energy Regulators

The Energy Regulators effects its control by periodically switching the power on and off, the ratio of the on time to the total time determining the average power input. As compared with a variable resistance, the energy regulators is in general cheaper, far less bulky, and applicable to any load up to its rated capacity. Moreover, the control is effected without the loss of energy associated with resistance control, is variable continuously from no load to full load and is substantially independent of mains voltage fluctuations up to about 20%.

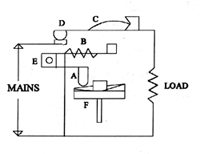

The energy regulators mainly consists of a heated bimetal and a snap-action switch (spring contact). Fig. 1 below will make the mode of operation clear.

- Is a bimetal strip holder carrying a cam follower whose function is to compensate for variations of ambient temperature

- Is a bimetal strip carrying a heater winding

- Is a snap-action switch operating the contact

- Is a knife edge about which the bimetal assembly can pivot

- Is a means of adjustment

Normally the contact D is closed so that current flows through the heater winding on the bimetal and through the load. The bimetal warms and, in bending, opens the switch C, interrupting the current both to the heater winding and to the load.

The bimetal then cools and the cycle is repeated. The ratio of the time during which the contacts are made, to the total time of the cycle, determines the average input.

This ratio is controlled by the adjusting cam F. Clearly if the cam is set so that the contacts remain closed with the maximum deflection of the bimetal, the power will be permanently on; if the cam is turned until the contact D is open with the bimetal cold, the power will be permanently off. Between these two limits the input is continuously adjustable.

Since the same voltage is applied to the energy regulators as is applied to the load, any variation will affect the two similarly, so that the average input is independent of applied voltage over a wide range.

| LINE INPUT | 230V + 20%, Single phase, 50Hz, 1kw Max, up to 3Kw for 3 hours Max. Can supply as per customer’s input specification |

| RANGE | 6% TO 85% adjustable |

| TEMPERATURE | Can adjust temperature up to 300 degree centigrade by dial setting |

| ISOLATION | 2.5kv A.C, for 1 minute, leakage current <3.5mA |

| LERAKAGE CURRENT | less than 210 micro Amp. As per IS 302 |

| OPERATING TEMPERATURE | 0 to 50 degree Centigrade |

| LIFE | 1,00,000 switching cycles under normal conditions |

| SAFETY | Meets VDE, IEC Standards |

| EMC | CE Marked |

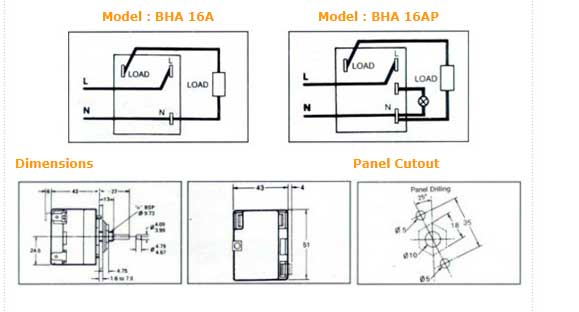

| DIMENSIONS | Length - 50mm width - 41mm height - 74mm approx. |

| WEIGHT | 110gm approx. without dial plate |

- Long duty cycle and short intervals between heating = greater average output, e.g. for heating up

- Short duty cycle and long intervals between heating = smaller average output, e.g. for simmering

- The output of the load can be set to between 6% to 85% of the rated output. Select highest setting for full nominal rating (100%).

- Infinitely variable control of the power supply

Energy regulators control is applied with saving and convenience to an extremely wide range of process heating apparatus replacing a resistance or potentiometer.

- In apparatus where it is inconvenient or impossible to fit any type of thermostat, e.g. hot plates, injection moulding nozzles, moulding patterns, etc.

- For small, high temperature ovens and furnaces where the costs of temperature control would be excessive.

- For any heating process where the temperature is a function of power input only.

- To control the rate of change of temperature in a furnace with a view to reducing the differential or temperature spread permitted by conventional temperature controllers.

- For controlling the input to a furnace so as to obtain rapid heating without undue overrun at the operating temperature.

- To control the average output of a motor driving, for instance, a conveyor or pump where there id no objection to the motor being periodically started and stopped, e.g. a pump filling a tank, a motor driving an automatic stoker or a belt travelling through a furnace.